Product Center

Service Hotline:

+86-13526692320- Tel/WhatsApp: +86-13526692320

- E-mail: sales@doinggroup.com

What is the fractional distillation of crude oil process?

Generally speaking, there are different design of distillation in the market, compared to other design, our new design crude oil distillation has obvious advantages ,which can save much time and cost for our clients.

Our distillation is of vertical reactor. This design is very good for our clients to discharge the residue out easily and fast. Secondly, our distillation with vertical reactor is connected with indirect heating system, in this way, the heat is circulating in inside the reactor. With indirect heating system, our client can save much cost on fuel and time, and they can continuously feed crude oil into the reactor without stop.

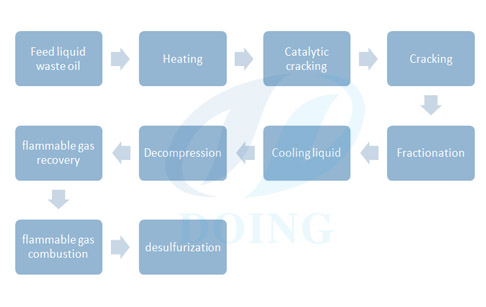

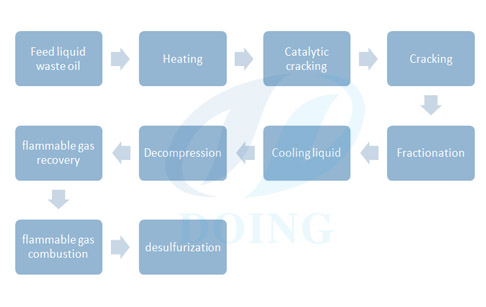

Please look at our fractional distillation of crude oil process flow chart:

fractional distillation of crude oil process

Also, ourfractional distillation of crude oil plant has many other advantages, welcome your visit and we will show your in front of our demo machine.

Fractional distillation of crude oil plant process in brief:

In our design, firstly, our clients need to heat the indirect heating system

Then the indirect heating system will transfer heat to reactor. And the heat will last for long time inside the reactor. Under high temperature, the crude oil will be pyrolysised into oil gas.And all the available oil gas will be cooled down by condensers and will be naturalized by chemicals. Finally, our client will get diesel for commercial and industrial usage.

To help you understand the diesel from ourfractional distillation of crude oil plant, here I share some pictures with you.

Our distillation is of vertical reactor. This design is very good for our clients to discharge the residue out easily and fast. Secondly, our distillation with vertical reactor is connected with indirect heating system, in this way, the heat is circulating in inside the reactor. With indirect heating system, our client can save much cost on fuel and time, and they can continuously feed crude oil into the reactor without stop.

Please look at our fractional distillation of crude oil process flow chart:

fractional distillation of crude oil process

Also, ourfractional distillation of crude oil plant has many other advantages, welcome your visit and we will show your in front of our demo machine.

Fractional distillation of crude oil plant process in brief:

In our design, firstly, our clients need to heat the indirect heating system

Then the indirect heating system will transfer heat to reactor. And the heat will last for long time inside the reactor. Under high temperature, the crude oil will be pyrolysised into oil gas.And all the available oil gas will be cooled down by condensers and will be naturalized by chemicals. Finally, our client will get diesel for commercial and industrial usage.

To help you understand the diesel from ourfractional distillation of crude oil plant, here I share some pictures with you.

Fractional distillation of crude oil plant

Request a Quote for Pyrolysis Plant

Please leave your contact information and pyrolysis plant requirements so that our professional team can contact you as soon as possible.